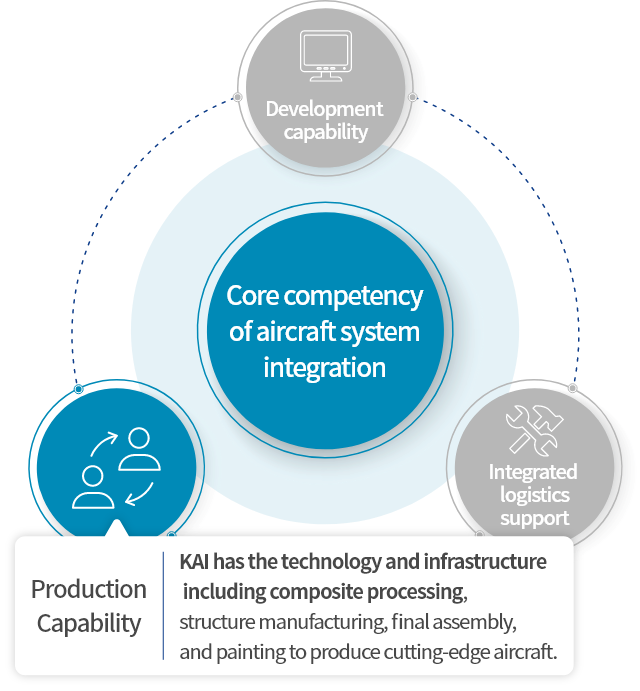

Production Capability

KAI has the technology and infrastructure including composite processing, structure manufacturing, final assembly, and painting to produce cutting-edge aircraft.

- Holds skilled production expert manpower with a diverse aircraft manufacturing experience and an experience of assembling the large-sized civil aircraft structure, like Boeing and Airbus.

- Builds up a concurrent engineering system which can simultaneously conduct production and design via a linkage to PLM and SAP-R3 which allow for integrated control in the pre-development process

- Adopts the global standard warranty system which satisfies quality requirements for manufacturing aircrafts worldwide and acquires AS9100.

KUH-1 Utility Helicopter, T-50 Advanced Jet

Trainer Final Assembly Site

-

Laminated Production for

B787 Composite Structure -

Wing Assembly Automation

with Robotic Drilling System(RDS) -

B777X Wing Rib

3D Measurement -

A350 Wing Rib

Automated Process -

T-50 Exterior Painting

-

KSLV-II

(Korea Space Launch Vehicle)

Oxidizer Tank Assembly